How to Clean Graphite Mold Effectively

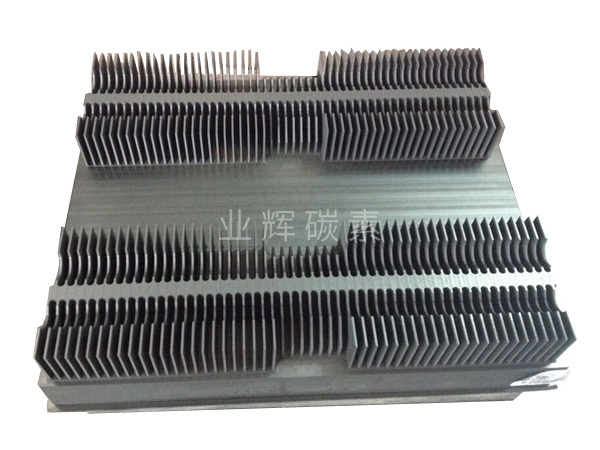

時間:2022-09-16瀏覽次數(shù):2330Graphite mouldIt needs to be cleaned and maintained after a long time of use. Cleaning is an important process in the maintenance of graphite moulds and also a bottleneck restricting the maintenance of graphite moulds. The manufacturing and development speed of graphite mould is much faster than the cleaning speed of graphite mould, and the graphite mould is ready for the next production immediately after rapid cleaning, so the cleaning time of graphite mould is very limited. According to the investigation, the graphite mould placed in the workshop corridor and workshop almost fills the limited working space of the workshop, just waiting for cleaning.

Some factories will hire junior technicians or apprentices to clean graphite molds and templates in the graphite mold workshop when cleaning and maintaining graphite molds, and maintenance technicians will remove graphite molds. However, in practice, cleaning graphite molds and templates will also wash away track marks, making it difficult for maintenance technicians to find and correctly repair defects in graphite molds and parts.

Graphite mold cleaning does not require advanced graphite mold making technician skills, but if you are not familiar with the special characteristics or defects of graphite mold, or do not understand the characteristics of the main sealing areas of graphite mold, beginners who do not know about it should be responsible for cleaning the graphite mold. A decision that was not considered at all. The unreasonable distribution of graphite mold cleaning work leads to performance defects in the continuous production of graphite molds. Due to joints, burrs, corners, premature electroplating or steel displacement, mixed graphite molds and other reasons, the graphite budget of molds has increased dramatically. These types of problems usually originate from the "fire fighting" maintenance culture, which does not monitor or explain defects, and does not identify the cause of the problem.

The system maintenance of graphite mould is based on the need of maintenance and continuity of maintenance work. In order to achieve the goal of "cost performance", attention should be paid to the cleaning of graphite mold: a detailed cleaning plan of graphite mold should be formulated. When cleaning different parts of the graphite mold, the cleaning methods used are different, such as internal pressure cleaning, edge wiping, conventional cleaning, main area cleaning, etc.

After the graphite mold runs for a period of time, visually inspect the electroplating wear, magnetic track trace, graphite mold residue in the exhaust and non exhaust areas, and the technician determines the graphite procedure and frequency, which I can do. Clean the mold by visual inspection. Therefore, it is very important to understand the safe operation period of the graphite mold and provide an observation report on the accumulation and wear of residues in the graphite mold.

Based on the specific operation cycle of graphite mould, all graphite moulds shall be attached with relevant maintenance procedures and maintenance cycle documents. Generally speaking, the key to ensure stable production is to control the internal grease level and movement of moving parts such as gear broach, sliding block, inner shaft pin and bushing. Other factors affecting production include scaling or plugging of water pipes and sprinkler inlets, manifold leaks, and rust and corrosion caused by water leaks and condensation.